TechnologyJanuary 16, 2026

Digital Transformation driven by AI & IIoT Megatrends

The full impact of Industrial AI is still a future possibility but the writing is already on the wall about its potential to transform edge computing and enterprise connectivity in the quest for digital transformation. In this special report, industry experts weigh in on the megatrends, and enabling technology solutions.

FOR AN UPDATE ON DIGITAL TRANSFORMATION, Industrial Ethernet magazine reached out to industry experts to get their perspective on the latest megatrends driving next generation industrial automation networking solutions.

According to experts, the future is a world where software-defined, data-centric platforms will create a fusion of AI with edge computing and emerging connectivity technologies. It’s a world where AI and the Digital Twin will redefine industrial machinery, and where Ethernet-APL and NOA Open Architecture will move us toward systems where secure, standardized access to data is aided by interoperable, vendor-neutral data exchange.

But at its core, digital transformation is focused on industrial communication, device integration and management, and new solutions for enterprise connectivity.

“Connected to AI is evolving and increased focus on edge computing. Edge computing brings AI resources close to the source of reliability issues to track and trend equipment health, helping personnel make critical decisions in real time,” Amy Schantz, vice president of engineering and new product development for Emerson’s Machine Automation Solutions business.

Evolution of AI and Edge Computing

New ways to measure, compute, predict, automate, and orchestrate.

According to Amy Schantz, vice president of engineering and new product development for Emerson’s Machine Automation Solutions business, generative and foundational model AI is evolving and increasingly focused on edge computing solutions in 2026.

“One of the biggest trends is generative and foundation model AI with large language models and various agents,” Schantz told Industrial Ethernet recently. “Much of the future of AI is unknown territory, and the potential for it to create new challenges can be unnerving, especially as we consider AI’s use in real-time, mission-critical applications. However, what we do know is that enabling intelligent automation with the help of AI copilots and agents is going to be central to both user experiences and increased productivity.”

Schantz added that, connected to AI, is evolving and increased focus on edge computing. Process upsets on the factory floor are incredibly disruptive, so teams must anticipate equipment failure and plan maintenance intervals. Edge computing brings AI resources close to the source of reliability issues to track and trend equipment health, helping personnel make critical decisions in real time. Edge computing is also unlocking improved quality, with vision systems more easily included in quality control, for example.

“Organizations are also generating tons of data today, so we need zero trust and continuous monitoring models for our cybersecurity so we can continue to protect that data,” Schantz said. “Data also needs to be managed and contextualized so it can feed the AI tools and ML models providing operational decision support. Emerging data fabrics and real-time analytics will help provide a boundless automation vision for context and observability to bring value to data from the floor to the edge and into the cloud.”

IIoT successes

Schantz said that the point is that IIoT is going to help us measure, compute, predict, automate, and orchestrate as we move forward in industrial systems. The existing and upcoming trends like GenAI and foundational models, edge computing, next-generation cybersecurity, and data fabric, will be coming together to make operations faster, smarter, more unified, and more secure.

IIoT-supported modern workers will increasingly improve their ability to communicate with their systems. Natural language interfaces and reasoning will bring alarms, logs, maintenance notes, and more together to help personnel make more informed decisions much faster. Knowledge synthesis across all the data will help staff understand and interpret what is going on in the factory, which will not only help operators feel more comfortable and effective but will also drive consistency.

“Ultimately, that increased decision support will help make every worker the company’s best worker—the distinctions between performance of different shifts will start to disappear and variability will be easier to manage. In an era of workforce shortages and a generation of workers moving between roles far more frequently, this capability to lock in institutional knowledge will become a critical driver of competitive advantage,” she concluded.

Industry applications

Schantz said that, in manufacturing, the evolution of edge computing has opened many opportunities to deploy solutions. For example, there is AI at the edge quality inspection—an example that we’re implementing at Emerson facilities. Using next generation PACSystems IPC platform combined with PACEdge, users can quickly and easily pass or fail equipment in quality inspection using AI tools and real-time inference. This solution can be scaled but remains air gapped in the factory, providing a low latency solution while allowing security to remain paramount. Edge analytics are also being deployed to deliver predictive maintenance for rotating equipment. Connected worker technologies are driving operational excellence, with AI copilots providing troubleshooting assistance in both operations and maintenance, and augmented reality overlays supporting decisions in the field.

In the process industries, edge computing helps improve critical operational metrics such as flare monitoring, valve performance, compressor behavior, and more. In addition, predictive corrosion and leak detection are critical capabilities being improved by increasing ability to use multimodal data. Data fabrics are also the foundation for new enterprise operations platforms built on scalable software-defined control, industrial AI, and zero trust cybersecurity to bridge existing automation with modern technologies, enabling unified data intelligence, advanced optimization, and autonomous operations.

Commercial buildings and smart infrastructure are also seeing benefits with increased energy optimization driven by real-time AI for HVAC control, occupancy detection, and more. Predictive maintenance for equipment such as elevators, HVAC, and pumps brings value in reduced failures and reductions of 10-20% in energy usage.

Challenges for automation engineers

“Right now, data is siloed, and industry needs to move toward unified, contextualized data to make the dramatic shifts in operational excellence that are necessary to meet today’s marketplace needs,” Schantz said.

Successfully leveraging that unified, contextualized data as part of a boundless automation vision will support the evolution that will reimagine the way factories operate. That data is going to feed the AI engines that drive toward fast, effective resolution and improvement. It feeds the FMEA and root-cause analysis tools that help predict failures and suggest resolution workflows to maintenance personnel. It drives real-time analytics and

GenAI agents and copilots that will build a new engineering workforce model, where engineers focus more on engineering judgement and system architecture, and less on coding and paperwork.

“Ultimately, we’re on a path where siloed data is becoming unified contextual data, making it possible for engineers to deliver faster project cycles and easier scaling that will help unify operations, drive innovation, and increase efficiency,” Schantz said.

“Unified, contextualized data will feed the more secure, next-generation automation technologies that provide fast response, are infinitely and intuitively scalable, and provide instantaneous decision support across every competency from the factory floor to the head office boardroom,” she added. “The result will be a transition to more autonomous operations, predictive rather than reactive maintenance, and faster engineering, development, and deployment cycles.”

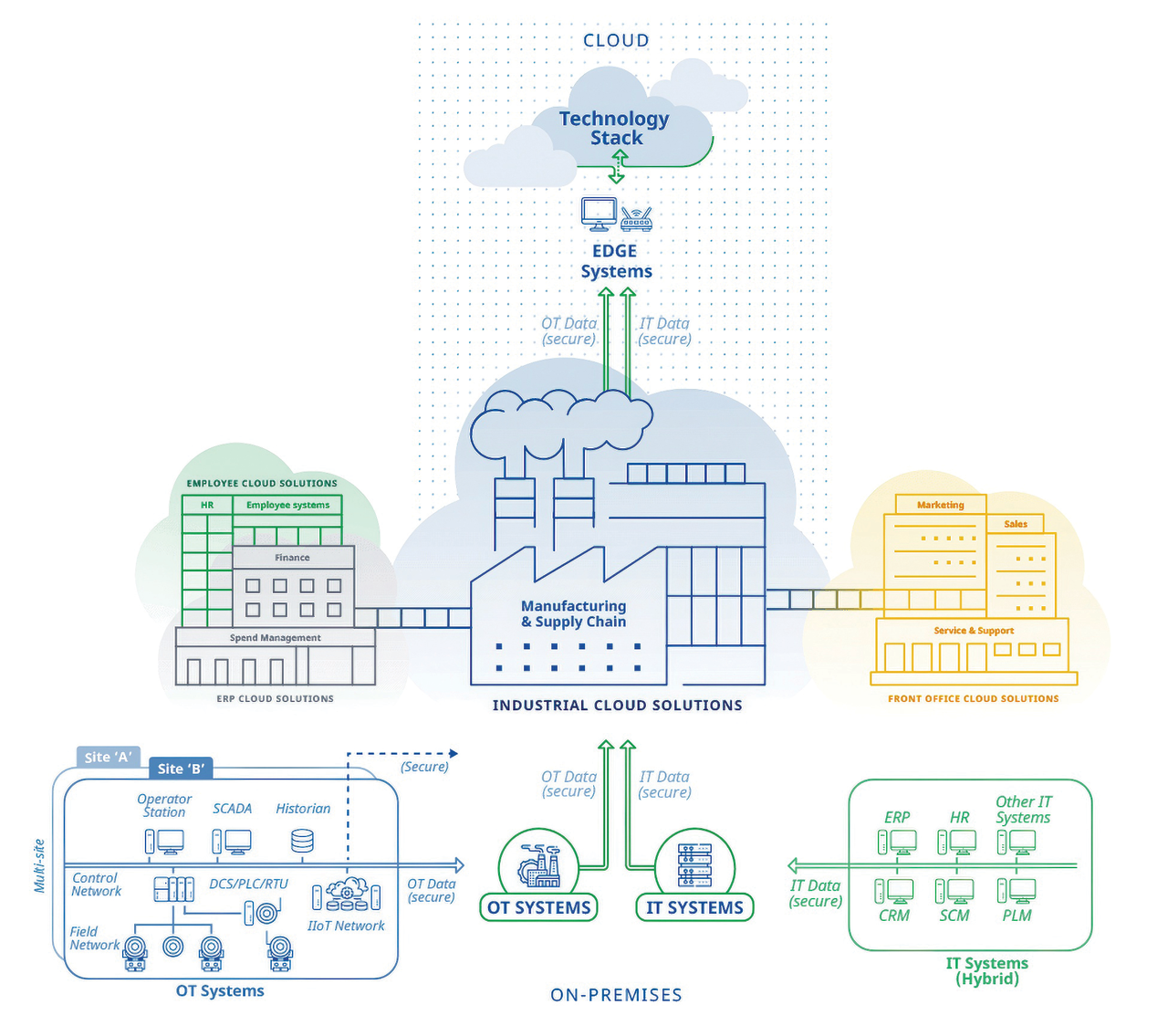

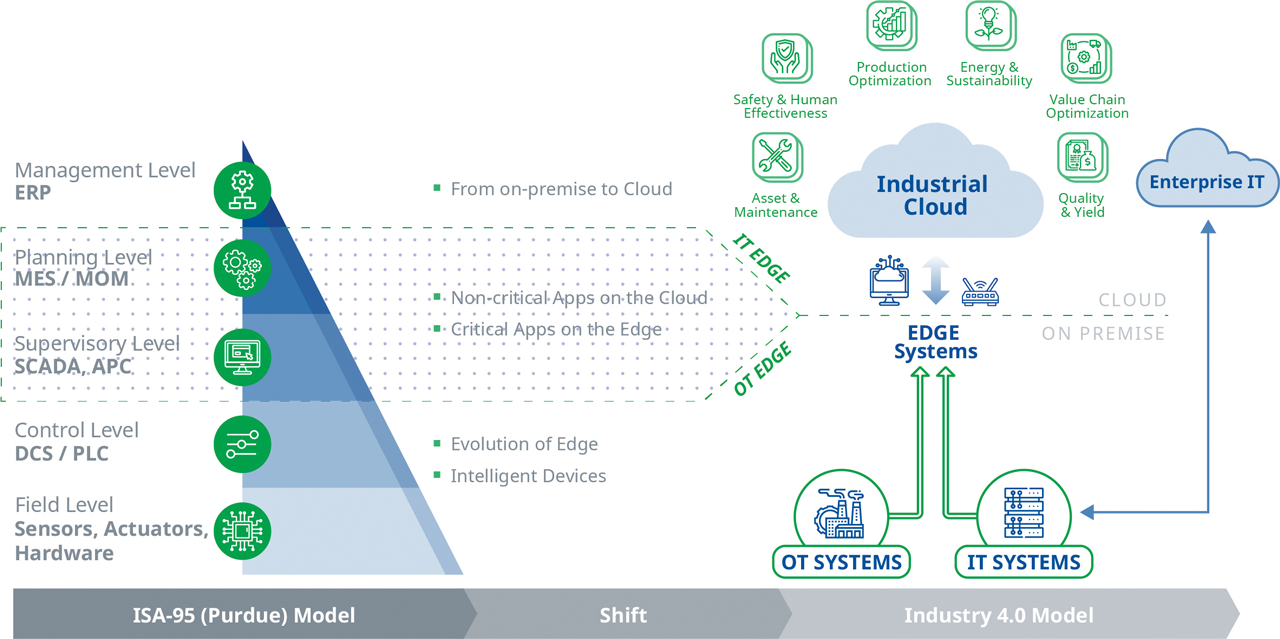

Industry 4.0 architectures simplify connectivity.

Software-Defined, Data-Centric Platforms

Future brings fusion of AI with edge computing and emerging connectivity technologies.

Karthik Gopalakrishnan, Solutions Consultant, Yokogawa, said that AI in combination with edge computing software solutions and emerging connectivity are the technologies and megatrends shaping and enabling the evolution of Digital Transformation in 2026.

“AI has moved from experimentation to large-scale operational deployment, particularly in industrial environments where edge AI enables real-time decision-making directly at machines and devices,” Gopalakrishnan said.

“At the same time, open standards such as OPC UA, MQTT Sparkplug B, and Open Process Automation (O-PAS) are replacing proprietary architectures, enabling multi-vendor interoperability. Emerging connectivity technologies—including private 5G, Wi-Fi 7, and Ethernet‑APL—are providing deterministic, high-bandwidth, and secure data transport from field devices through the enterprise. Together, these trends are transforming IIoT systems into software-defined, data-centric platforms capable of continuous optimization.”

Secure connectivity based on standards provides pathways for communication.

Enabling technologies and solutions

Gopalakrishnan said that the IIoT delivers hard real-time, synchronized control across multi-vendor systems without proprietary fieldbuses, making it possible to implement controller-to-controller and motion applications on standard Ethernet. Edge AI allows inference and anomaly detection to occur within milliseconds at the device or production line, reducing latency, bandwidth, and dependence on cloud availability.

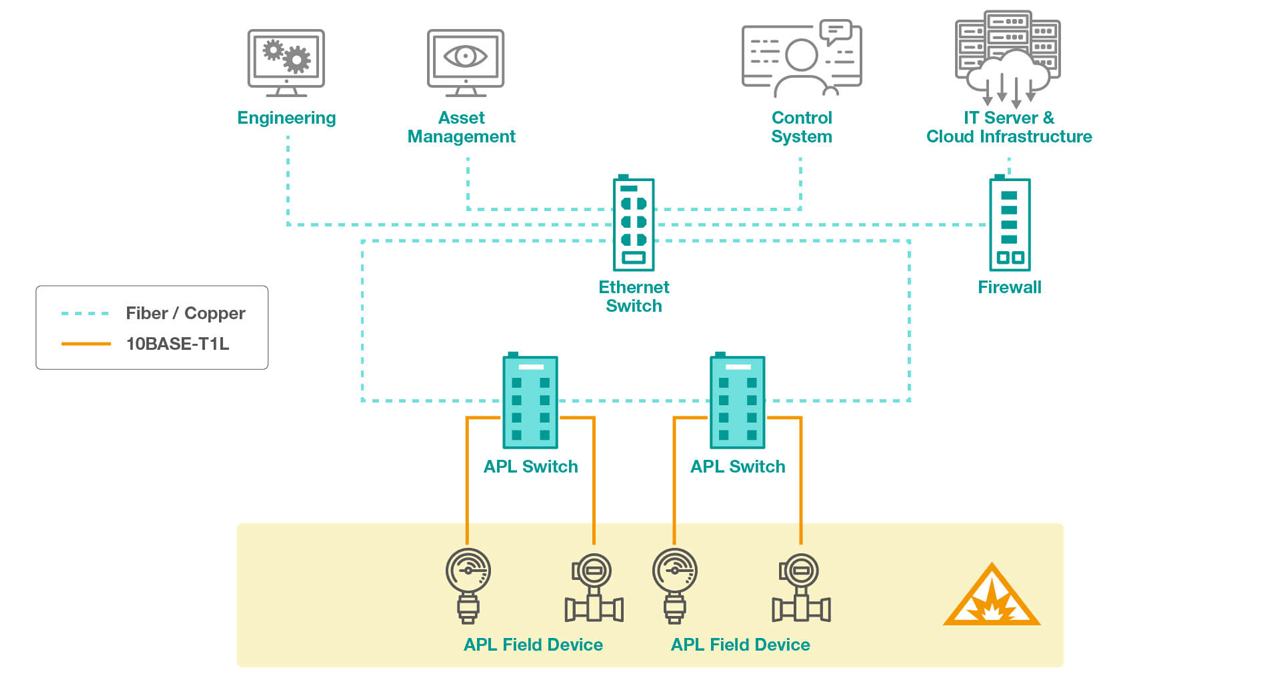

Ethernet APL extends Ethernet all the way to intrinsically safe field instruments using two-wire power and data, unlocking rich diagnostics and faster commissioning. MQTT Sparkplug B standardizes industrial data context and device lifecycle management, dramatically reducing integration effort compared to custom MQTT or traditional point to point architectures.

Industry impact

“Manufacturers are deploying private 5G networks to support autonomous mobile robots, machine vision, and flexible production layouts with seamless mobility,” Gopalakrishnan said. “Process industries are adopting Ethernet APL and NAMUR Open Architecture (NOA) to extract diagnostics and operational data from brownfield plants without disturbing core control systems. Digital twins—fed by real-time IIoT and edge analytics—are being used to optimize production, energy usage, and maintenance strategies, while open DCS architectures based on O PAS are demonstrating lower lifecycle costs and faster system upgrades. These applications are gaining traction because they directly address long-standing operational constraints.”

Looking ahead, he concluded that technologies are creating a series of important benefits moving forward that will impact smart manufacturing.

“Open standards eliminate vendor lock-in and reduce the engineering effort required to integrate heterogeneous systems. Deterministic networking and edge computing resolve latency and reliability issues that previously limited advanced control and AI use cases,” Gopalakrishnan said. “Open architecture technologies provide practical pathways for modernizing legacy brownfield plants without disruptive rip-and-replace projects. In parallel, compliance-driven cybersecurity frameworks, such as the IEC 62443 directive, are embedding security-by-design into automation systems, transforming security from an afterthought into a core engineering discipline.”

“Solutions such as the Digital Twin and AI—including traditional, generative and now agentic—have helped businesses become more flexible, resilient and efficient while setting the foundation for increased automation that keeps the human in the loop,” — Rahul Garg, VP for Industrial Machinery Vertical Software Strategy, Siemens Digital Industries Software.

Turning steel into gold

How AI and the Digital Twin will redefine industrial machinery.

Rahul Garg, VP for Industrial Machinery Vertical Software Strategy, Siemens Digital Industries Software, said that technologies such as the Digital Twin are helping to bring automation dreams into reality.

“Becoming a digital enterprise is no longer optional. Combating labor shortages and decreasing profit margins have driven machine builders in the industrial manufacturing industry to jump into their digital transformation journeys,” Garg said. “Solutions such as the Digital Twin and AI—including traditional, generative and now agentic—have helped businesses become more flexible, resilient and efficient while setting the foundation for increased automation that keeps the human in the loop. “

“Digitalization is now the key to competitiveness; and the comprehensive Digital Twin combined with digital threads are the foundation of digitalization, connecting every stage of a product’s lifecycle, from concept to manufacturing, into a single source of truth,” Garg said. “Additionally, digital threads unify processes and systems, enabling seamless collaboration across departments and promoting the integration of new technologies.”

AI and comprehensive digital twins: democratizing digital transformation

Garg’s view is that the dynamic shift in industrial machinery, driven by the integration of AI across design, operations and supply chains, will continue to disrupt the sector for years to come. Accessibility is key as AI capabilities accelerate, and enterprises of all sizes look to modernize their systems and processes. Updating business processes may initially seem intimidating for SMBs and brownfields, but there are solutions that ease access to automation and AI processes which are growing increasingly important as talent gaps continue to widen.

Large language models (LLMs), for example, have been empowering workers to dabble with AI. Only last year, many manufacturers began deploying LLMs to fill in knowledge gaps and bridge human and machine operations. Starting with these simple tools gives designers and engineers time to adapt to new solutions so that the company can determine their specific AI needs and build from there. Incrementally leveraging AI-infused solutions that address engineering and manufacturing needs will ultimately simplify the adoption of more complex and powerful solutions on the horizon.

Once a company knows where and when to include AI in its operations by identifying value use cases, it can begin training in-house AI models. At this point, machine builders, for example, can fully integrate generative AI and agents into their processes to create new engineering and manufacturing content and even automate complex workflows.

Achieving a more automated factory that is ready to face a volatile landscape starts with a plan. To create a solid plan, OEMs should look to the Digital Twin for virtual commissioning. It is crucial to test how and where certain processes will work before integrating new machines or processes into more traditional workflows. The Digital Twin of the factory creates an accurate, real-time virtual representation of their factory that is accessible for workers across teams and disciplines.

Harmonizing humans, robots, and automation through digitalization

“Digitalization does not always mean scrapping old, reliable equipment and replacing it all with new machinery. Many OEMs have seen ROI from integrating collaborative robots (cobots), or robots that aid human workers during production,” Garg said.

“Cobots enable seamless integration between automated and manual systems, allowing machine builders to put them where they are needed without upending processes that work for them. Leveraging cobots, a brownfield environment can quickly evaluate how to upgrade operations and become a state-of-the-art facility.”

Garg added that a factory that has fully integrated the Digital Twin can also implement AI in tandem to supercharge operations. Machine builders can create immersive settings that perfectly imitate physical factories and production lines to accelerate robot training and programming. In this virtual classroom, robots can practice tasks, address common challenges and develop problem-solving skills in just hours, rather than months or even years.

Digital Twin and AI capabilities further lay the groundwork for budding technologies such as humanoid robots. Humanoids are poised to shake up the industrial manufacturing space and will likely enter the factory floor within the next few years. As a result, virtual commissioning powered by the Digital Twin will become even more important. Virtual commissioning will be at the heart of harmonious operations between humans, cobots, smart robots and humanoids; enabling the factory to forecast human interactions with automated systems and equipment.

The pivot from hardware to software

“With the rapid advancements in technology, industrial manufacturing is under pressure to tackle skill shortages, unpredictable supply chains, and increasing demand for more resource-efficient and sustainable production,” Garg said.

Autonomous operations help machine builders address current challenges and position them to tackle future ones. As part of this shift, automation is transitioning from hardware-based devices to software-defined functionalities. Software-defined automation (SDA) combines information technology (IT) flexibility with operational technology (OT) robustness.

Now, instead of relying on fixed hardware for functionality, SDA uses software to control, enhance and update features, making it more adaptable and scalable. Brownfields, for example, can take special advantage of SDA because it enables connection between legacy equipment and systems to more modern data-driven services and applications. Once these machines are connected, older factories can begin to craft their own digital thread and move towards greater automation and accelerated operations.

Journey, not destination

“Industrial machinery is entering its next golden age. Success in 2026 will hinge on the industry’s ability to stay afloat as the AI revolution keeps or even accelerates its momentum. For machine, equipment and component manufacturers, the digital enterprise model represents a transformative approach where every aspect of the business is interconnected through data, automation and real-time insights,” Garg concluded.

“By integrating the Digital Twin and leveraging AI, organizations can move beyond outdated, fragmented systems and build flexible frameworks that address both current and future challenges. As more companies adopt this approach, it has become clear that embracing digital transformation is imperative to ensuring sustained agility and long-term success in this new age of manufacturing.”

“A key enabler is the adoption of standard Ethernet as a universal communication backbone, now extended to the field level with Ethernet-APL, a version of Ethernet designed for long-distance, high-speed, and intrinsically safe connectivity in process plants. Standardized data models such as NOA, an open architecture concept for secure, standardized access to device and process data, and PA-DIM, a standardized model for representing device information, are enabling interoperable, vendor-neutral data exchange” — Hermann Berg, Head of Industrial Automation, Moxa Europe.

Ethernet-APL and NOA Open Architecture

Secure, standardized access to data, driven by interoperable, vendor-neutral data exchange.

“The evolution of digital transformation in process automation is being driven by several converging megatrends and enabling technologies,” according to Hermann Berg, Head of Industrial Automation at Moxa Europe.

“A key enabler is the adoption of standard Ethernet as a universal communication backbone, now extended to the field level with Ethernet-APL (Advanced Physical Layer), a version of Ethernet designed for long-distance, high-speed, and intrinsically safe connectivity in process plants.

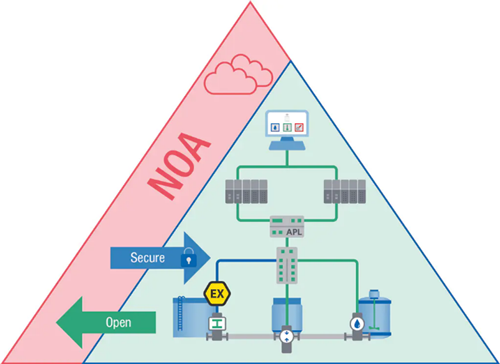

Standardized data models such as NOA (Namur Open Architecture), an open architecture concept for secure, standardized access to device and process data, and PA-DIM (Process Automation Device Information Model), a standardized model for representing device information, are enabling interoperable, vendor-neutral data exchange,” Berg said.

He added that this is essential for scalable and flexible digitalization. The AAS (Asset Administration Shell’), a digital twin concept providing a standardized digital representation of assets, supports integration across the entire lifecycle. Together with advanced cybersecurity mechanisms, these technologies create a secure, future-proof infrastructure that supports Industrial IoT, predictive maintenance, and data-driven optimization. This foundation is enabling process industries to accelerate their digital transformation, unlocking new efficiencies and business models.

IIoT application successes

Berg said that standard Ethernet and Ethernet-APL enable uniform, high-bandwidth connectivity from the enterprise level down to field devices, reducing traditional silos and proprietary protocols. This allows for real-time data access and seamless integration of IT and OT systems.

Standardized data models like NOA and PA-DIM ensure that data from diverse sources is structured, contextualized, and easily consumable by analytics and AI applications. The AAS further enhances interoperability by providing a standardized digital twin for every asset. Combined with robust cybersecurity, these solutions enable secure remote access, scalable cloud integration, and advanced IIoT applications such as predictive maintenance, process optimization, and adaptive control. Compared to legacy systems, this approach dramatically reduces integration effort, increases flexibility, and accelerates innovation in process automation.

Applications in industry

NAMUR Open Architecture (NOA) enables IT applications to securely access data from process control systems, the core of chemical, petrochemical, and pharmaceutical production, without compromising system integrity. Implementing NOA starts with securing the OT network, beginning in the Core Process Control (CPC) zone.

In the process industries, these technologies are being applied to enable open, modular automation architectures and to support the integration of both legacy and new assets. Ethernet-APL is being deployed in greenfield and brownfield projects to connect field instruments directly to digital platforms. NOA and PA-DIM are facilitating standardized data exchange for condition monitoring, asset management, and regulatory compliance. The AAS is being used to create digital twins that streamline engineering, commissioning, and lifecycle management.

A particularly promising application is the secure, remote firmware update of field devices. With open, standards-based connectivity across the entire plant, operators can efficiently manage firmware updates for a diverse range of devices, ensuring security patches and feature enhancements are deployed consistently and with minimal disruption. This capability, previously limited by proprietary protocols and fragmented networks, is now becoming a practical reality. It helps to maintain cybersecurity, improve device performance, and extend asset lifecycles.

Other applications gaining traction include predictive maintenance, remote diagnostics, and process optimization, all of which rely on secure, standardized data flows. The anticipated impact is a significant increase in operational efficiency, reduced downtime, and the ability to rapidly adapt to changing market and regulatory requirements.

Challenges and ongoing impact

“These technologies address key challenges such as system complexity, vendor lock-in, and cybersecurity risks. By leveraging standard Ethernet and open data models, engineers can design modular, interoperable systems that are easier to maintain and scale,” Berg said. “Ethernet-APL simplifies field device integration and supports intrinsic safety requirements NOA and PA-DIM can reduce engineering effort by providing standardized interfaces for data access and analytics.”

“The AAS enables consistent asset management across the lifecycle. Robust cybersecurity mechanisms ensure that digitalization does not compromise plant safety or reliability,” Berg added. “Moving forward, these technologies are expected to continue enabling innovation, helping automation engineers focus more on value creation than system integration, and supporting process plants in staying agile and competitive in a rapidly evolving digital landscape.”

“Ethernet-APL technology is gaining broad traction as a new physical layer for devices in automation facilities, allowing end-to-end Ethernet connectivity from the plant floor to the cloud. Ethernet Advanced Physical Layer (Ethernet-APL) is a protocol agnostic physical layer that provides open interoperability and high-speed data transfer,” — Paul Sereiko, Director- Marketing and Product Strategy at FieldComm.

The Core of Digital Transformation

Industrial communication, device integration and management, and enterprise connectivity.

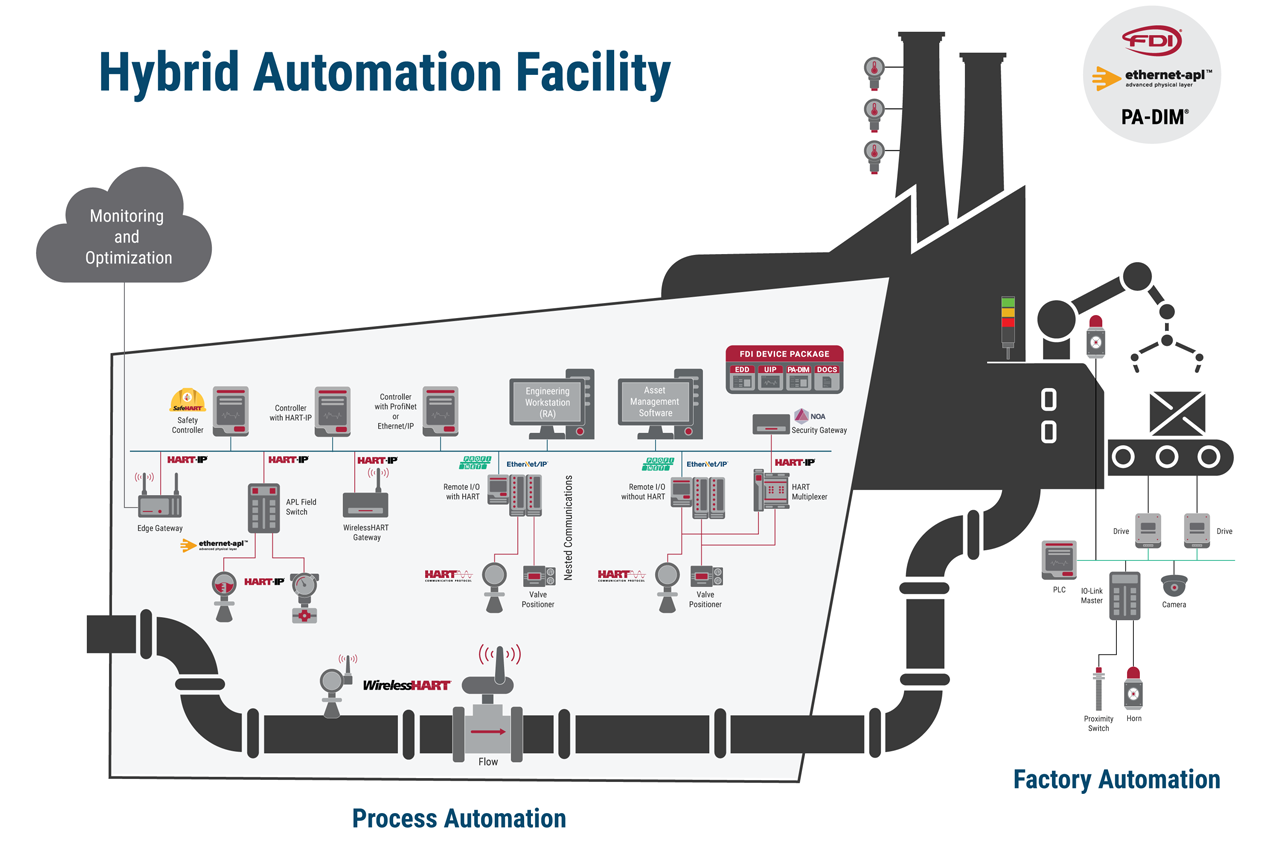

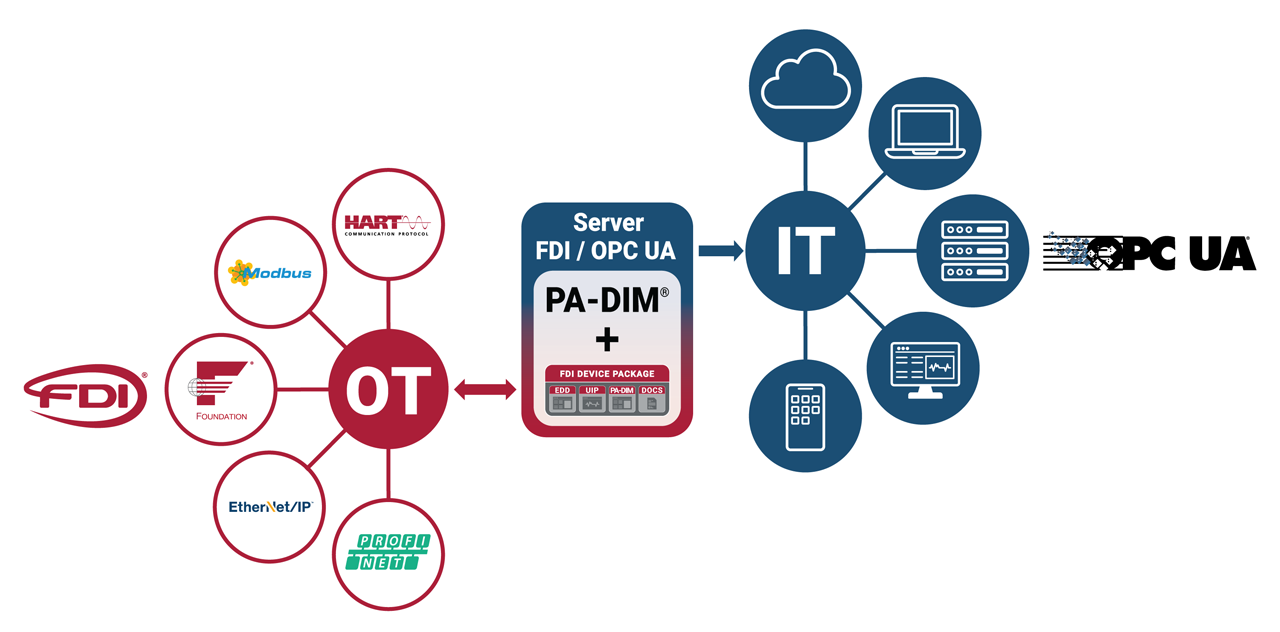

FieldComm Group focuses on three areas of technology that form the core of digital transformation: industrial communication, device integration and management, and enterprise connectivity.

According to Paul Sereiko, Director- Marketing and Product Strategy at FieldComm, “Ethernet-APL technology is gaining broad traction as a new physical layer for devices in automation facilities, allowing end-to-end Ethernet connectivity from the plant floor to the cloud. Ethernet Advanced Physical Layer (Ethernet-APL) is a protocol agnostic physical layer that provides open interoperability and high-speed data transfer directly from the field-level to control and higher-level enterprise applications.”

Sereiko said that industrial protocols like HART that have previously been bound by slow physical layers are now being recast to support high speed communications via Ethernet-APL and Single Pair Ethernet (SPE) technology. The broad base of users familiar with HART technology can now leverage their existing knowledge base to take full advantage of HART-IP over Ethernet with no additional training requirement.

“The industrial internet of things (IIoT) requires sensors to be deployed wherever physical measurements are needed. To manage these devices, operators want unified device integration within their device and asset management systems,” Sereiko said. “This allows devices using different protocols to connect and communicate in a standardized way and provides access to intelligent data for analytics and predictive maintenance.

Device integration technologies like Field Device Integration (FDI) and Field Device Tool (FDT) are designed to make this standardized integration into higher-level systems possible.”

He added that, to make sure that information from these intelligent devices is understood throughout the enterprise, users are beginning to deploy device information models used in conjunction with OPC UA technology. Process Automation Device Information Model (PA-DIM) forms the basis of NAMUR Open Architecture and will become a commonplace feature in industrial instrumentation devices and systems.

The convergence of OT and IT networks is an important catalyst for digital transformation.

Synergies working together

Sereiko said that, while each of the solutions described above provide benefits to users engaged in digital transformation, the real benefits accrue when all are used together. Developing and deploying sophisticated plant optimization programs requires secure access to massive amounts of easily understood information from the devices operating at the lowest level of the Purdue model, the field instruments.

“Today’s consumers of this information, basically sophisticated IT and machine learning systems, face almost insurmountable challenges in economically accessing the information. For example, the IT system will generally not be able to understand protocol-specific information from the automation system, the instrumentation cannot provide sufficient data due to bandwidth limitations, and information is lost in protocol translation,” Sereiko said.

“So, for the past decade, suppliers and standards organizations have been working together to chip away at these issues. Fortunately, the technologies are now well thought out and ready to deploy,” he added. “All the technologies discussed are either in commercial deployment, small scale plant trials, or in R&D evaluation at facilities around the world including Germany, China, and the United States. Ethernet-APL is being installed in many locations.”