TechnologyJanuary 16, 2026

Special Report: Time-Sensitive Networking Update

The ability to provide deterministic communication over standard Ethernet networks, and achieve converged network performance, is the main premise behind TSN technology. Industrial suppliers weigh in on why TSN is now increasingly considered a strong candidate for scalable, multi-vendor smart manufacturing networks.

TIME-SENSITIVE NETWORKING SOLUTIONS are pressing ahead based on a goal of providing deterministic communication over standard Ethernet and converged industrial networks.

The update from technology suppliers is that growing support for TSN standards has resulted in increased integration of IEEE/TSN features into Custom-Of-The-Shelf (COTS) network chips for Ethernet end-nodes and switches as well as support in popular operating systems such as Linux.

The argument is that TSN is gaining momentum in factory automation as manufacturers are looking to move toward open, unified network architectures and closer IT/OT convergence. As standards and industry profiles mature, TSN is increasingly considered a strong candidate for scalable, multi-vendor smart manufacturing networks.

Digitalization of Modern Manufacturing

Technology addresses the challenges of deterministic communication over standard Ethernet, and converged networks.

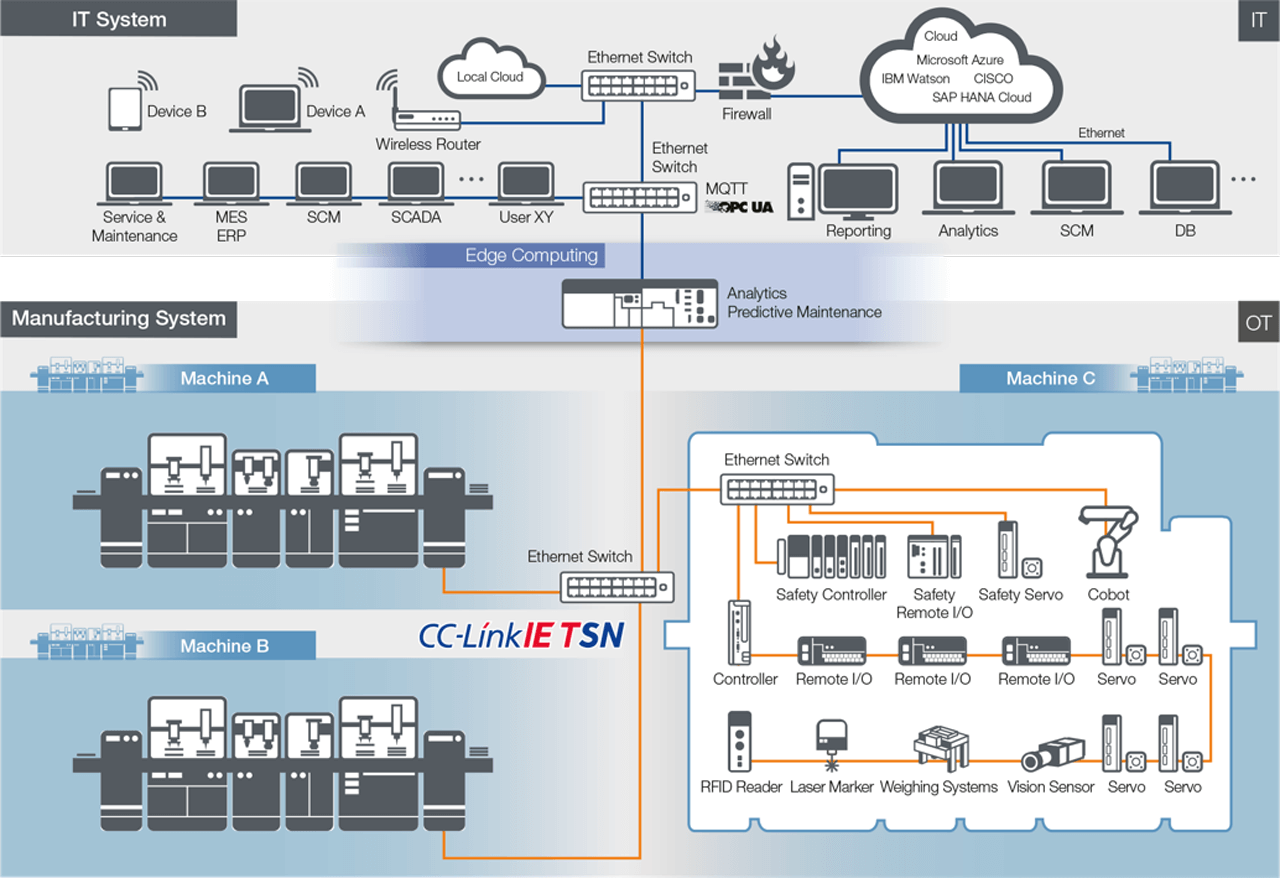

“Time Sensitive Networking (TSN) has become established in factory automation because it addresses the challenges of digitalization in modern manufacturing,” John Browett, General Manager for CC-Link Partnership Association Europe. “These divide into two main areas: deterministic communication over standard Ethernet and converged networks. Traditional industrial networks often rely on proprietary protocols or segmented architectures to guarantee real-time performance, which limits flexibility and scalability. TSN changes this paradigm by introducing IEEE 802.1 standards that enable precise time synchronization and traffic shaping on converged Ethernet networks.”

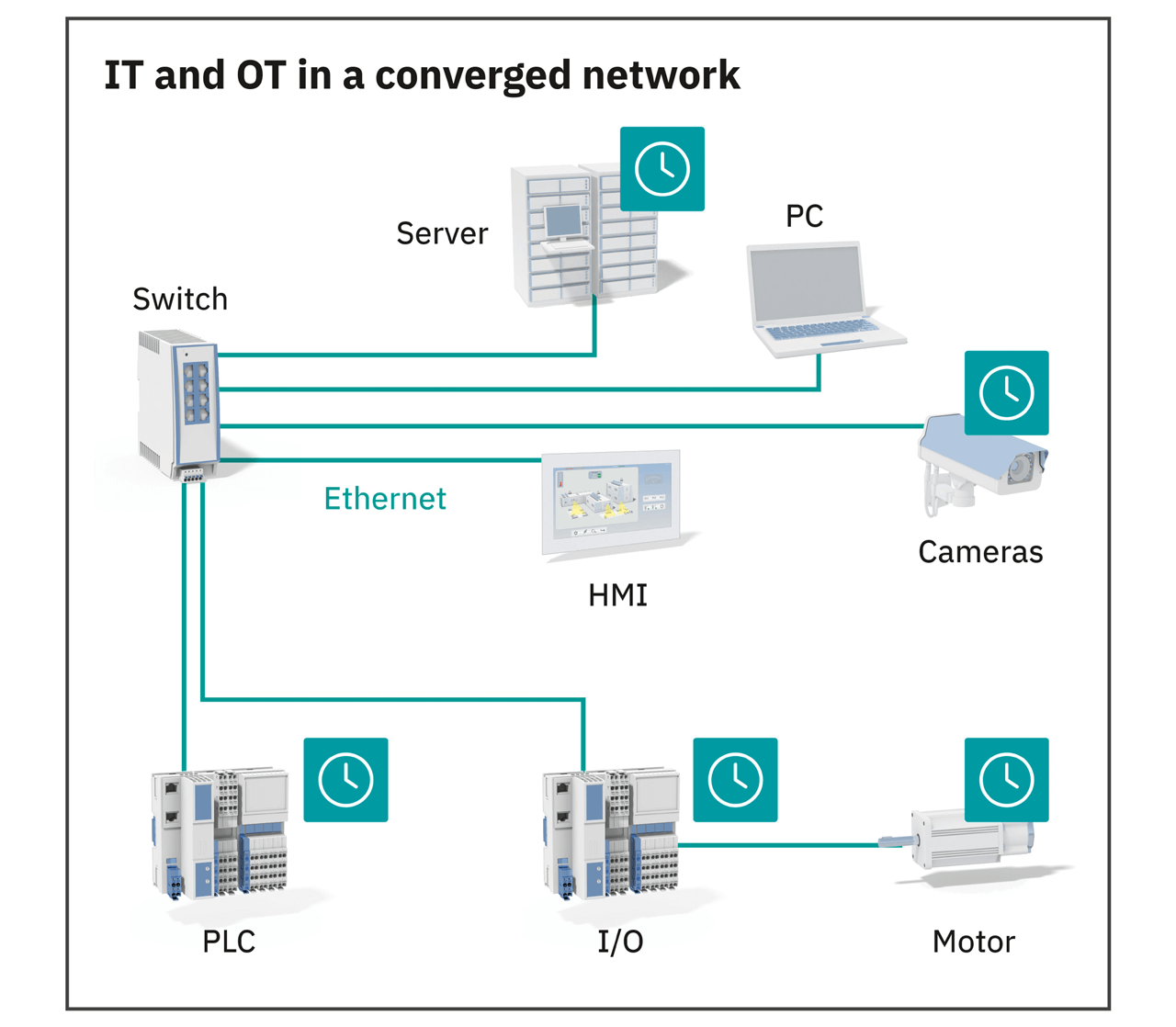

Browett said that manufacturers are increasingly adopting TSN as they address digitalization and smart factories, where machines, sensors, and IT systems must share a common infrastructure without sacrificing real-time control. TSN allows motion control, safety-critical traffic, and OT/IT non-critical TCP/IP data to coexist on the same network, reducing complexity and cost.

Deployments have been rolled out in over a 100 different manufacturing corporations worldwide, which is driving machine builder support and in turn device vendor adoption. Sample applications are automotive assembly lines, packaging systems, food and beverage, semiconductors and consumer electronics, where deterministic performance and interoperability are essential. As more device vendors certify TSN compatibility, adoption is accelerating, supported by open ecosystems and standardization efforts such as IEC/IEEE 60802 and TIACC that make TSN a future-proof choice for industrial automation.

Specific TSN technology benefits

Browett said that TSN delivers three core benefits that make it highly attractive for factory automation: deterministic communication, network convergence, and vendor-neutral interoperability. Unlike traditional Ethernet, TSN guarantees bounded latency and jitter through time-aware scheduling and traffic shaping, ensuring that critical control data arrives predictably even under heavy network load. This is vital for applications like motion control and robotics, where microsecond-level timing accuracy is non-negotiable.

Second, TSN enables convergence of IT and OT traffic on a single Ethernet infrastructure. This reduces cabling, simplifies network design, and lowers lifecycle costs compared to maintaining separate networks for control and enterprise data. Third, TSN is based on open IEEE standards, making it vendor-neutral and future-proof, unlike proprietary real-time Ethernet solutions that lock customers into specific ecosystems.

“Compared to some current industrial Ethernet technologies, TSN offers scalability beyond factory floors, extending into edge computing and cloud integration without sacrificing determinism,” Browett said. “Its ability to coexist with standard Ethernet traffic while maintaining real-time guarantees sets TSN apart as the foundation for truly integrated smart manufacturing networks.”

TSN adoption is strongest in industries where precision, flexibility, and interoperability are critical. Automotive manufacturing is a leading sector, driven by complex assembly lines that require synchronized motion control and real-time quality monitoring. TSN enables these environments to integrate robotics, vision systems, and safety devices on a single converged network, reducing complexity and improving responsiveness.

Packaging and food & beverage machinery builders are also early adopters, as these industries demand high-speed coordination between multiple axes and rapid changeovers for customized production runs. TSN’s deterministic performance ensures smooth operation even as data volumes grow with IIoT sensors and predictive maintenance systems.

Additionally, semiconductor and electronics manufacturers are adopting TSN for its ability to support ultra-low latency control alongside large volumes of process data. System integrators serving these sectors see TSN as a way to future-proof installations, offering customers a migration path from proprietary fieldbus systems to open, Ethernet-based architectures. Overall, TSN appeals to machine builders and end-users seeking to combine real-time control with IT/OT convergence for smarter, more agile production environments.

The industrial network connects assets to intelligence.

Impact of TSN technology

“In the next three years, TSN is expected to become a cornerstone technology for smart manufacturing, enabling unprecedented levels of integration and flexibility,” Browett said. “As more device vendors and automation platforms adopt TSN standards, manufacturers will gain the ability to consolidate control, safety, and data traffic on a single Ethernet backbone. This convergence will simplify network architectures, reduce hardware costs, and accelerate deployment of advanced digital solutions such as predictive maintenance and AI-driven analytics.”

He added that TSN will also play a critical role in enabling edge-to-cloud connectivity without compromising real-time performance. This capability is essential for closed-loop optimization, where production data informs immediate adjustments to improve efficiency and quality. Furthermore, TSN’s interoperability will foster multi-vendor ecosystems, reducing vendor lock-in and encouraging innovation.

“Expect to see TSN integrated into next-generation controllers, drives, and industrial PCs, making it a default choice for new installations and retrofits. As digitalization initiatives mature, TSN will transform factory networks from isolated islands into unified, deterministic platforms that support both operational excellence and digital transformation,” Browett said. “Finally, activities like IEC/IEE 60802 and TIACC will ensure that there is standardization across the industry, ensuring TSN will be a truly open technology base as we move into the future.

“More and more automation devices can support TSN standards. This is possible thanks to the integration of the corresponding IEEE/TSN features into Custom-Of-The-Shelf (COTS) network chips for Ethernet end-nodes and switches, as well as support in popular operating systems such as Linux,” – Gunnar Lessmann, Master Specialist Profinet and TSN – PLCnext Technology, Business Area Industry Management and Automation, Phoenix Contact.

Growing Support for TSN Standards

Integration of IEEE/TSN features into Custom-Of-The-Shelf (COTS) network chips for Ethernet end-nodes and switches.

According to Gunnar Lessmann, Master Specialist Profinet and TSN – PLCnext Technology, Business Area Industry Management and Automation, Phoenix Contact, “More and more automation devices can support TSN standards. This is possible thanks to the integration of the corresponding IEEE/TSN features into Custom-Of-The-Shelf (COTS) network chips for Ethernet end-nodes and switches, as well as support in popular operating systems such as Linux.”

Lessmann said that this integration enables device manufacturers to produce products more easily and cost-effectively on platforms which are available from multiple manufacturers with a wider chip variety. In earlier times, e.g. expensive FPGA technology was necessary to support TSN.

In the meantime, international standardization activities such as IEC/IEEE 60802 and TIACC cover manufacturer-independent profiling and testing of TSN platforms. IEC/IEEE 60802 and TIACC are set up by Standards Development Organizations (SDOs) such as Avnu Alliance, CC-Link Partner Association, ODVA, OPC Foundation, and Profibus & Profinet International. By working together, these SDOs are committed to providing end users with confidence that their IEC/IEEE 60802 compliant devices will coexist fairly at the TSN level on shared networks, regardless of differences in manufactures or differing supported automation protocols.

“With the availability of suitable platforms and products, TSN will increasingly find its way into automation solutions of many application areas, not only factory automation,” Lessmann added.

Preferred choice in factory automation applications

“The biggest advantage of TSN is the integration of multiple disciplines in a common, converged network. This makes it possible to use video streams, real-time communication, alarms and events, high-precision time synchronization, motion control applications and other TCP/IP communication in a single network,” Lessmann said. “One converged network reduces effort and costs for planning, installation, maintenance and operation of machines and systems compared to solutions that are using separate networks for each discipline.”

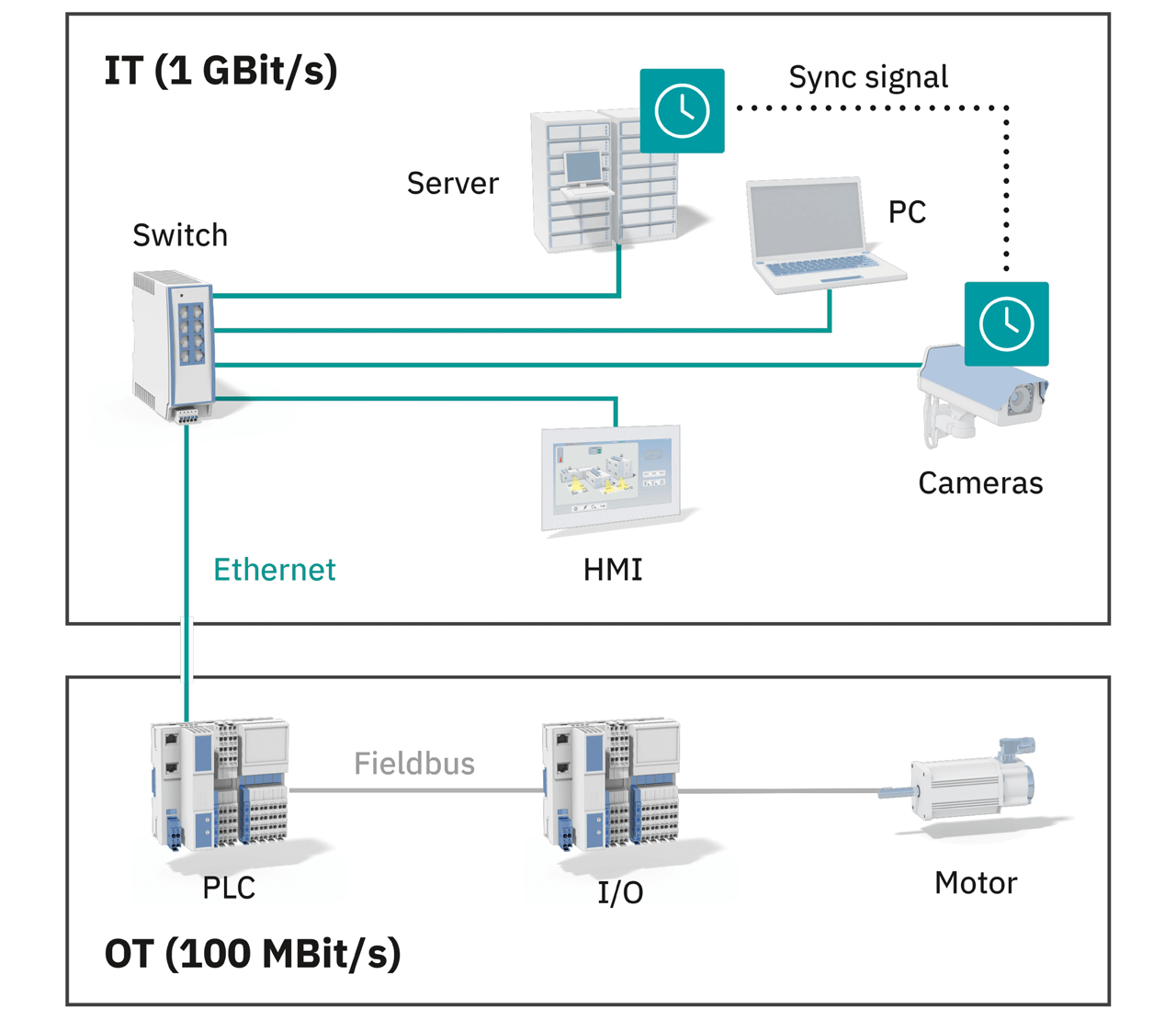

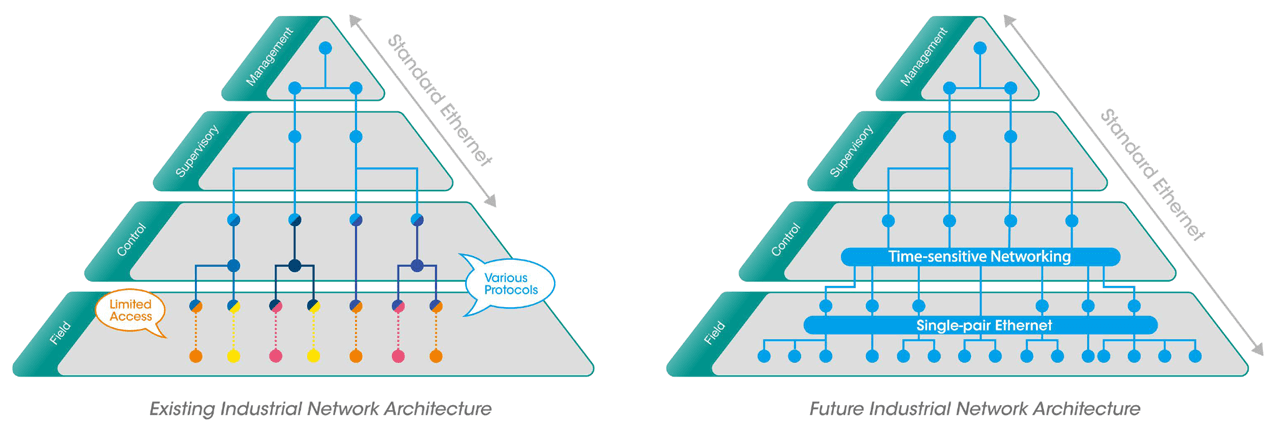

Lessmann added that separated Networks for IT and OT are today’s standard in factory automation (see diagrams). While one encapsulated communication system is used for real-time-critical applications (Fieldbus). A separated network is installed for all the other more “IT-like” traffic. This separation should be overcome leading to the following picture:

In a converged network all devices regardless of whether OT or IT are integrated in a single network. One prerequisite for such a network is the availability of Ethernet bandwidth of minimum 1Gbit/s in devices of the TSN-backbone. Nevertheless, devices with lower link-speeds like 100Mbit/s can be connected and used if this case is specified by the particular SDO. E.g. with Profinet, existing devices can be used in combination with those supporting TSN.

Separated Networks.

Converged Network with TSN.

Types of applications and customers

Lessmann said that, in addition to the use in classic factory automation scenarios, applications of renewable energy generation such as wind farms should be mentioned. Due to increased requirements of grid operators, an entire wind farm, for example, must be able to react within milliseconds to new setpoint values of the grid operators.

This is only possible if the communication and control applications of all participating devices are synchronized with each other. Furthermore, it must be possible to provide events in the energy grid with highly accurate timestamps whose resolution is better than 100μs. Both cases are not possible without the application of TSN standards. This makes TSN also an enabling technology for the energy production of the future.

Furthermore, the COTS integration mentioned above enables the use of TSN in combination with virtual PLCs on standard hardware and thus completely new use-cases like realtime-critical motion-control applications running in data centers. This requires a converged network as precondition.

The next 1-3 years?

“We expect the integration of TSN features into the products of all well-known automation manufacturers and SDOs. Along with the standardization of profiles and tests, the functionality, quality and interoperability of TSN solutions will increase,” Lessmann said. “This is a continuous process that will continue over the next 1-3 years and behind. Depending on the capability of the SDO to integrate existing devices into new TSN networks, a smooth transition from today’s separated networks to one integrated TSN network is possible.”

“TSN is gaining momentum in factory automation as manufacturers move toward open, unified network architectures and closer IT/OT convergence. By enabling deterministic, low-latency communication over standard Ethernet, TSN supports tighter synchronization for real-time control across machines, sensors, and controllers. As standards and industry profiles mature, TSN is increasingly considered a strong candidate for scalable, multi-vendor smart manufacturing networks,” — Hermann Berg, Head of Industrial Automation at Moxa Europe.

TSN Gaining Momentum

Manufacturers move toward open, unified network architectures and closer IT/OT convergence.

According to Hermann Berg, Head of Industrial Automation at Moxa Europe, “TSN is gaining momentum in factory automation as manufacturers move toward open, unified network architectures and closer IT/OT convergence. By enabling deterministic, low-latency communication over standard Ethernet, TSN supports tighter synchronization for real-time control across machines, sensors, and controllers. As standards and industry profiles mature, TSN is increasingly considered a strong candidate for scalable, multi-vendor smart manufacturing networks.”

Unique technology benefits

Berg said that TSN stands out in factory automation due to its unique combination of deterministic Ethernet, time synchronization, and traffic prioritization. Unlike traditional Ethernet or proprietary solutions, TSN provides standardized mechanisms to help ensure deterministic delivery of time-critical data with minimal jitter and bounded latency, which is essential for real-time control and safety applications. Its open, standards-based approach allows seamless integration of devices from multiple vendors, reducing vendor lock-in and future-proofing investments.

TSN also supports network convergence, enabling both control and non-control traffic to coexist on a single network without compromising performance. This flexibility can simplify network design and maintenance, while supporting the scalability required for modern manufacturing environments.

TSN gaining a foothold in smart manufacturing

“We’re seeing interest from OEMs, system integrators, and end customers that need deterministic motion/control traffic alongside standard IT data on the same Ethernet infrastructure, especially where multi-vendor interoperability is a priority,” Berg said. “Key sectors include automotive manufacturing, semiconductor production, and process industries such as packaging and intralogistics, where precise coordination of robots, sensors, and controllers is critical.”

“We’re seeing interest from OEMs, system integrators, and end customers that need deterministic motion/control traffic alongside standard IT data on the same Ethernet infrastructure, especially where multi-vendor interoperability is a priority,” Berg said. “Key sectors include automotive manufacturing, semiconductor production, and process industries such as packaging and intralogistics, where precise coordination of robots, sensors, and controllers is critical.”

He added that customers implementing digital transformation strategies, such as predictive maintenance, adaptive manufacturing, and integrated quality control, are leveraging TSN to unify disparate networks and support time-critical control traffic alongside standard data on the same Ethernet infrastructure, enabling seamless data flow from the edge to the cloud.

Use cases show how TSN has enabled flexible production lines, improved machine-to-machine communication, and supported the integration of legacy equipment with new digital platforms. These examples demonstrate TSN’s value in both greenfield and brownfield environments.

Looking ahead

“In the next 1–3 years, TSN is expected to accelerate the digital transformation of manufacturing by providing a robust foundation for converged, real-time industrial networks,” Berg said. “Manufacturers will benefit from increased operational efficiency, reduced downtime, and enhanced flexibility as TSN enables seamless integration of IT and OT systems.”

“The adoption of TSN will also facilitate the deployment of advanced applications such as AI-driven analytics, digital twins, and autonomous production lines,” he added. “As industry standards continue to evolve and more interoperable devices become available, TSN will drive the shift toward open, scalable, and future-ready manufacturing architectures.”