New ProductsJanuary 30, 2026

Direct and Secure Communication for Field Devices with OPC UA FX (Field eX-change)

B&R is among the first vendors to have successfully implemented this protocol into its products, taking field communications to the next level. The ACOPOS M4 is one of the first servo drives in the world to be developed natively on OPC UA FX.

As a member of the OPC Foundation’s Field Level Communication Initiative, B&R, ABB’s Machine Automation Division, is among the first vendors to have successfully implemented this protocol into its products, taking field communications to the next level. The ACOPOS M4 is one of the first servo drives in the world to be developed natively on OPC UA FXTM.

Open Platform Communication Unified Architecture (OPC UA) is a vendor-neutral communication platform, the first truly open protocol to have widespread industry support. In combination with Time-Sensitive Networking (TSN), OPC UA FX can provide a solution to the compatibility challenge of legacy real-time, field-level factory networks and is a secure key technology for industrial communication networks, enabling real-time communication in the industrial environment.

B&R is among the first vendors to have successfully implemented this protocol into its products, taking field communications to the next level. The ACOPOS M4 is one of the first servo drives in the world to be developed natively on OPC UA FX.

OPC UA FX specifically extends the core OPC UA standard to address the requirements of field-level devices, enabling drives, I/O modules, sensors, and instruments to communicate directly, securely and deterministically.

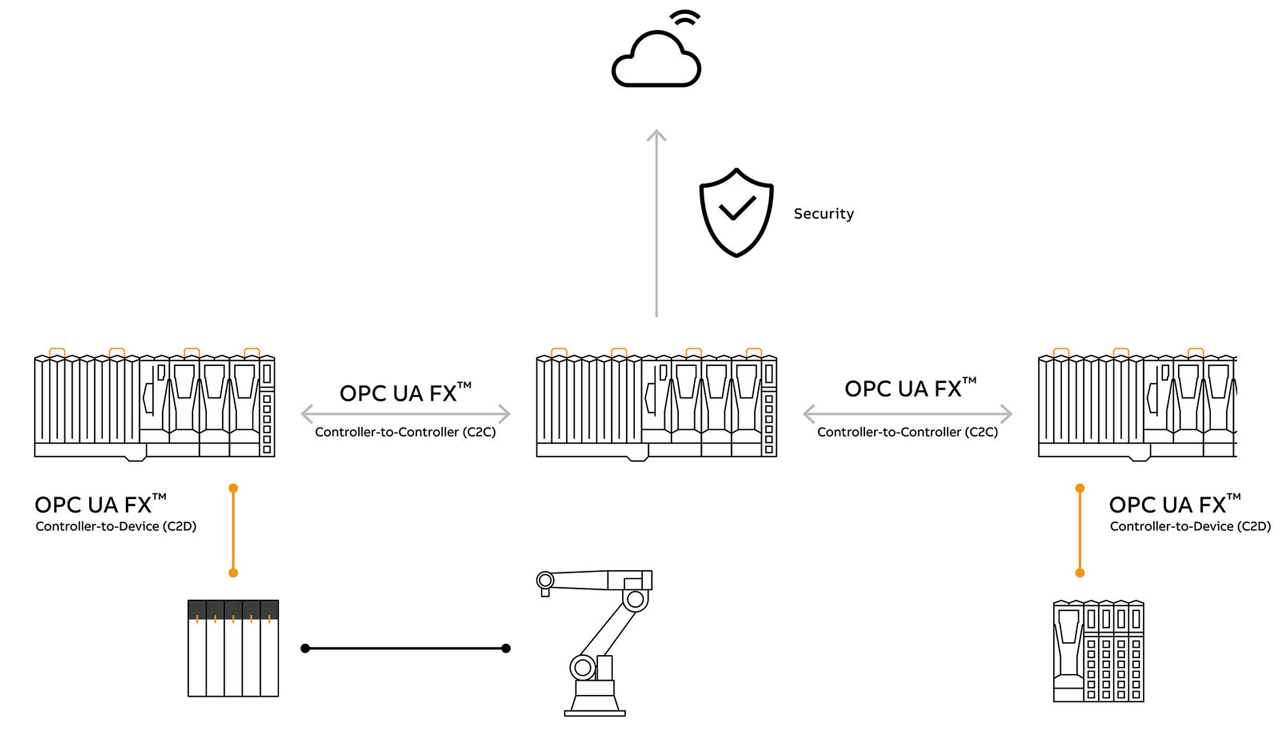

B&R’s industrial PCs, panel PCs, PLCs and network infrastructure components, already come with built-in support for OPC UA FX C2C (Controller-to-Controller) communication, providing an open, vendor-independent foundation for next-generation automation architectures. In the industrial world, our customers are often faced with a jumble of networking standards that don’t work together, making machine automation more complicated than it needs to be. Our mission with OPC UA FX is to change that,” said Veli-Pekka Ketonen, Product Manager Industrial Networks at B&R Industrial Automation.

The newly launched ACOPOS M4 from B&R is one of the first servo drives in the world to be developed natively on OPC UA FX. It is designed to unlock the full potential of this next-generation fieldbus for future, truly plug-and-produce machine automation. The OPC UA FX Technology Package from B&R extends OPC UA to the field level, thereby supporting both C2D (Controller-to-Device) and C2C scenarios*. It combines software, controllers, remote IO and network components into a single, cyber-secure solution. With ACOPOS M4 at its core – and integrating the X20BC008T bus controller and a TSN switch – the full potential of this next-generation industrial communication platform can be realized.

OPC UA FX has built in robust cyber security capabilities, minimizing potential attack vectors and ensuring resilient and trusted operations even in the face of evolving threats. The platform simplifies compliance to (amongst others) the CRA, a European Union regulation that establishes mandatory cybersecurity requirements for products with digital components. This ensures that users are prepared for current and future cybersecurity requirements and threats. OPC UA FX comes natively with secure communication channels and user authentication.

This provides a more robust security environment, compared to legacy fieldbus protocols. Built in certificate management removes error-prone configuration steps by automating the certificate lifecycle. OPC UA FX extends secure, deterministic communication to field-level devices, enabling open and interoperable architectures for next-generation automation. With ACOPOS M4 and integrated TSN support, B&R delivers a unified solution for real-time control, cybersecurity compliance, and streamlined machine integration.

Key benefits

For machine builders

- Seamless integration for faster machine development

- Built in security

- Open and interoperable; no lock-in to proprietary technologies

For end users

- Cyber Security capabilities addressing the EU Cyber Resilience Act (CRA)

- Reduced network complexity

- Streamlined data exchange across plant floors and enterprise systems