TechnologyJanuary 28, 2026

The Missing Middle: Solving the Logic Solver Gap in SIS Design

Why safety professionals need a new class of logic solver, one that bridges the enormous gap between safety PLCs and single-loop devices.

The logic solver is the decision engine of every Safety Instrumented System (SIS). It evaluates process inputs, applies voting logic, and initiates the action that ultimately reduces risk. Despite its importance, logic solver selection has traditionally forced engineers into a binary choice: either a fully featured Safety PLC or a single-loop logic solver (alarm trip).

Both approaches are well established, but they were designed for fundamentally different problem sets. As a result, a large portion of modern SIS applications lands uncomfortably between them; too complex for single-loop devices, yet far too small to justify a Safety PLC. This mismatch is what many practitioners recognize as the logic solver gap, and it has quietly cost industry time, money, and unnecessary complication for years. The gap is more than just an inconvenience; when neither traditional option fits cleanly, engineers are forced into compromises that become difficult to defend during hazard reviews, audits, or incident investigations.

The Limits of Traditional Choices

Single-loop logic solvers, often referred to as alarm trips, have evolved significantly. Many now include onboard diagnostics, password protection, easy-to-use menus, and configurable logic settings. They are fast to commission and easy to maintain. But their limitation becomes apparent when more than one loop needs to be monitored, or when voting logic must be implemented without extensive relay inter-wiring. They simply weren’t designed for multiloop safety applications.

Safety PLCs, on the other hand, certainly can handle small safety applications, but they do so with substantial overhead. Programming often requires licensed software and specialized skills. Their configuration and validation may demand additional documentation, and lifecycle costs are frequently much higher than the initial purchase price. For SIS applications in remote operations, temporary facilities, skid-based systems, wellheads, or burner management units, a Safety PLC is often technologically excessive, financially prohibitive, or operationally inefficient.

The Application Reality Engineers Face

In practice, many SIS designs involve only a handful of safety functions. Typical requirements include:

- One to three independent safety loops

- Moderate I/O counts (often 6–12 points total)

- Simple voting logic such as 1oo2 or 2oo3

- Localized deployment on skids, packages, or remote units

- Straightforward proof testing and validation

The Emergence of the Multiloop Logic Solver

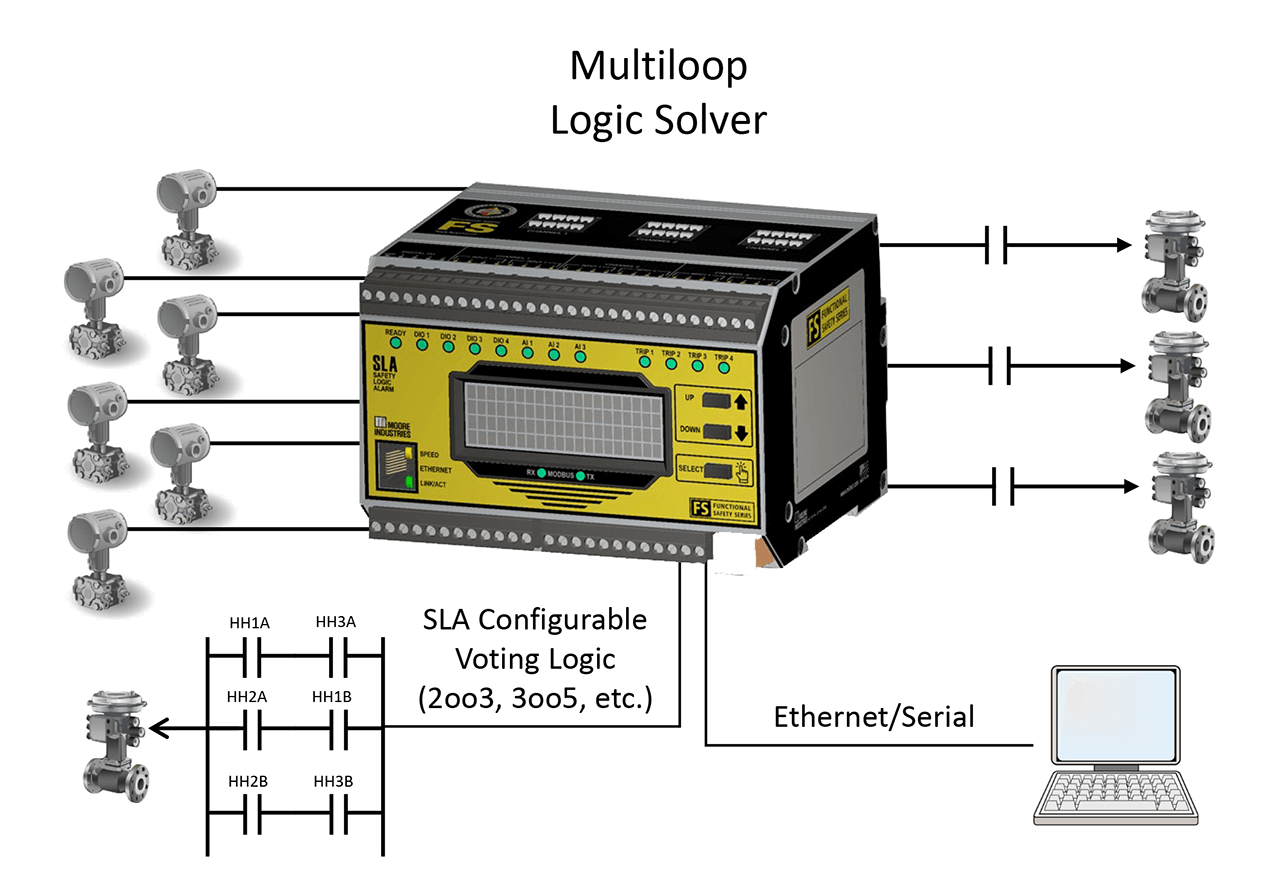

These midrange solvers thrive in places where Safety PLCs feel like overkill: pump shutdowns, burner management, wellhead safety, small-scale overpressure protection, tank protection, clean-in-place systems, and localized trip systems. They also integrate exceptionally well with existing BPCS or PLC infrastructures, especially in hybrid safety strategies where a larger safety platform handles core systems, while multiloop logic solvers are deployed at peripheral or isolated SIFs.

Rather than routing all safety logic through a central platform, many facilities are deploying localized safety nodes dedicated to specific hazards or process units.

Modular SIS Architectures and Localized Safety

Across oil & gas, chemical, and energy industries, SIS architectures are becoming more modular and decentralized. Rather than routing all safety logic through a central platform, many facilities are deploying localized safety nodes dedicated to specific hazards or process units.

Multiloop logic solvers fit naturally into this approach. By localizing voting and trip decisions, they reduce wiring complexity, shorten commissioning time, and simplify proof testing. Validation becomes more straightforward because fewer components and interconnections are involved. This directly supports IEC 61511 lifecycle expectations by reducing proof test complexity and minimizing the scope of revalidation when safety logic changes.

Integration Without Compromising Independence

Modern multiloop logic solvers also address visibility and diagnostics. Read-only communication interfaces such as MODBUS, Ethernet diagnostics, or HART pass-through allow safety status and device health to be monitored without undermining safety independence.

This capability supports asset management, audit readiness, and maintenance planning while preserving the integrity of the safety function; particularly valuable in hybrid architectures that combine centralized safety platforms with localized protection layers.Completing the Logic Solver Spectrum

Multiloop logic solvers do not replace Safety PLCs, nor do they diminish the value of single-loop devices. Instead, they complete the logic solver spectrum by providing a right-sized option for applications that have long been underserved.

For safety professionals seeking designs that are easier to validate, simpler to maintain, and better aligned with actual risk, the “missing middle” is no longer a niche solution, it is rapidly becoming a core architectural element of modern SIS design.

Engineering Decision Matrix: Choosing the Right Logic Solver

| Selection Criterion | Single-Loop Logic Solver | Multiloop Logic Solver | Safety PLC |

|---|---|---|---|

| Typical loop count | 1 | 1-3 | 3 to dozens |

| Typical I/O density | 1-2 points | 6-12 points | High |

| Voting logic | External relays required | Internal 1oo2 / 2oo3 | Fully programmable |

| Configuration method | Menu-driven | Menu-driven | Licensed software |

| SIL capability | SIL 1-2 | SIL 2-3 (Architecture Dependent) | SIL 2-3 |

| Validation effort | Very low | Low to moderate | High |

| Lifecycle cost | Low | Moderate | High |

| Best-fit applications | Single trips, alarms | Localized multiloop SIS | Large or complex SIS |

| Risk of over-engineering | Low | Low | High for small systems |

| Risk of under-engineering | Moderate | Low | Low |